The coolest sustainability innovations at Ecosperity 2019

Can we maintain our quality of life and feed humanity without costing the earth? Innovators shared how they are transforming current modes of production and consumption at Ecosperity Week in Singapore.

Food grown in Singapore. High-tech vertical farming is an efficient way to produce food within cities while minimising transport costs and carbon emissions. Will it enable Singapore to reach its goal of producing 30 per cent of its food locally by 2030? Image: Eco-Business

Food grown in Singapore. High-tech vertical farming is an efficient way to produce food within cities while minimising transport costs and carbon emissions. Will it enable Singapore to reach its goal of producing 30 per cent of its food locally by 2030? Image: Eco-Business

From biopolymer straws which are truly biodegradable to lab-grown shrimp, innovators presented their solutions for steering humanity towards a more sustainable future at the Ecosperity Showcase in Singapore.

The solutions, which addressed ways to improve our energy, waste and food systems, aimed to redefine consumption patterns and revolutionise some of the most polluting industries to tackle the world’s most pressing problems.

Here are some of the coolest innovations we saw at Ecosperity 2019.

Beating plastic pollution

The world’s disposable plastic addiction causes a mind-boggling 12 million tonnes of plastic to enter our oceans every year, threatening marine ecosystems.

Even those usually unmoved by environmental issues would have awakened to plastics pollution when microplastics were found in human stools for the first time last year, confirming that the material has entered our bodies through the food chain.

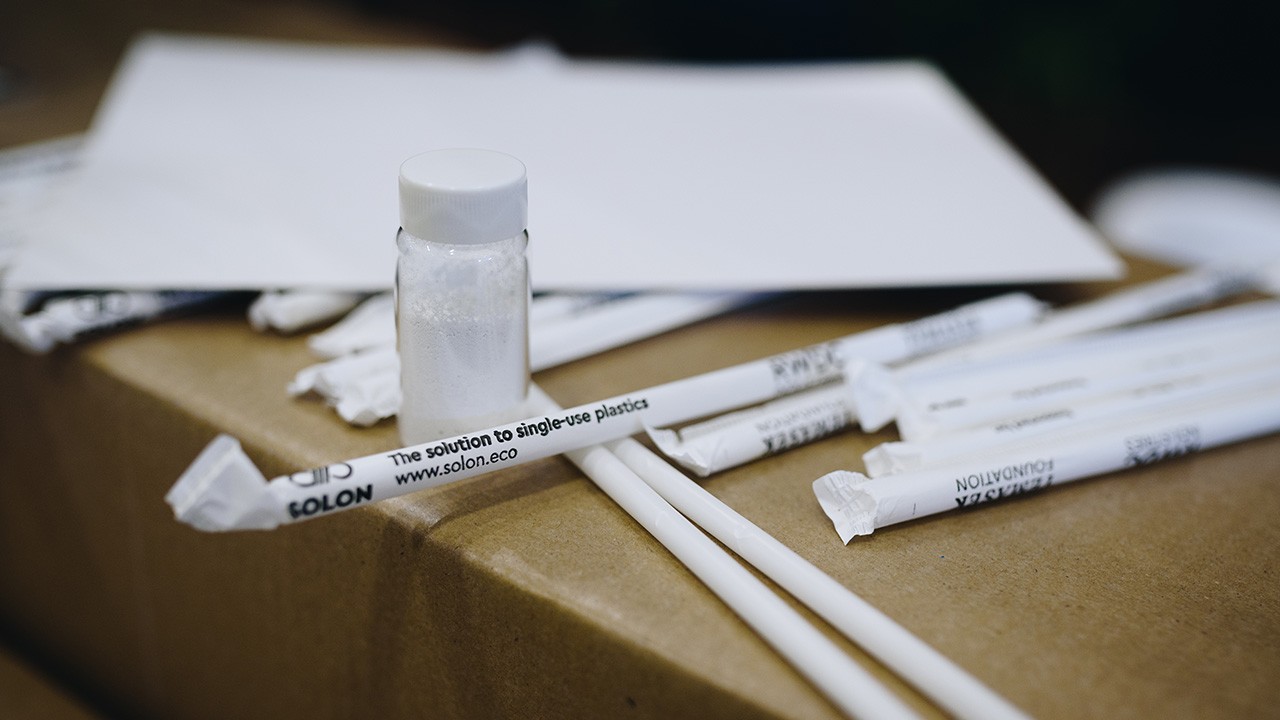

Singapore-based firm RWDC Industries showcases its biodegradable alternative to single-use plastics. Image: Eco-Business

Singapore-based firm RWDC Industries showcases its biodegradable alternative to single-use plastics. Image: Eco-Business

In 2018, Singapore alone uses 2.2 million plastic straws a day. This is deeply ingrained in people’s everyday lives, but a survey the same year showed that 80 per cent of Singaporeans were actually ready to ditch the habit, provided there are sustainable alternatives.

This is where RWDC Industries comes in.

The Singapore-based company, which won last year’s edition of sustainability solutions contest The Liveability Challenge, has developed a biodegradable and highly versatile single-use plastics alternative from plant-based oils. The material can be used not only to produce drinking straws, but also cutlery, cups, and food containers.

The firm intends to scale up production and make its straws available in commercial quantities, starting in Singapore later this year.

Taipei-headquartered company Miniwiz recycles post-consumer waste to produce a wide range of products from sunglasses and shoes to building materials and furniture. The use potential of trash is thus unlocked. Image: Eco-Business

Taipei-headquartered company Miniwiz recycles post-consumer waste to produce a wide range of products from sunglasses and shoes to building materials and furniture. The use potential of trash is thus unlocked. Image: Eco-Business

At the other end of the value chain, Taiwanese recycling company Miniwiz seeks to have a different sort of impact. Dedicated to unlocking the potential of the things we discard, the firm upcycles post-consumer trash and industrial waste to create products ranging from sunglasses and furniture to building materials and boats.

To tackle waste and enable recycling everywhere, the company has created a mobile recycling machine. The “Trashpresso” plant runs on solar power — making it deployable off-grid — and recycles plastic trash into architectural tiles.

The Miniwiz booth at Ecosperity 2019, showcasing the full potential of trash through its structure, furniture and products on display. Image: Eco-Business

The Miniwiz booth at Ecosperity 2019, showcasing the full potential of trash through its structure, furniture and products on display. Image: Eco-Business

Upcycled fashion on the rise

Air travel, waste and the consumption of meat and dairy products are all notorious for their environmental impact, but less often do people think about their carbon footprint from the clothes they wear.

Resources used to produce clothes pollute the air, water and soil, and yet, nearly three-fifths of clothing is discarded within a year of being produced. The apparel and footwear industries also account for close to 10 per cent of global carbon emissions.

To explore how fashion can meet consumer demand while protecting the environment, Singapore-headquartered investment company Temasek — host of the annual Ecosperity Conference — launched its first-ever upcycling competition titled Trash to Fash.

Trash to Fash tasked participants to create apparel that appeals to contemporary youths using only upcycled materials and recycled fabric made of PET bottles.

The winning ensembles of Temasek’s upcycling competition on display at the Ecosperity showcase

The winning ensembles of Temasek’s upcycling competition on display at the Ecosperity showcase

From lab-grown shrimp to Singapore-grown strawberries

By 2050, the United Nations estimates that world population will reach 9.7 billion, and 68 per cent of us will live in urban areas.

Feeding nearly 10 billion mouths with a food supply threatened by climate change and land degradation calls for a radical transformation of the way we produce and consume food.

Animal agriculture already accounts for about 15 per cent of total greenhouse gas emissions. Over 90 per cent of the world’s marine fish stocks are estimated to be overexploited overfished or fully fished. Until now, land-based solutions such as shrimp farming have exacerbated the problem by destroying mangroves and polluting waters in countries like Vietnam, Thailand and Indonesia.

The world’s population is growing faster than ever. Cutting-edge vertical farming could be one approach to sustain it.

The world’s population is growing faster than ever. Cutting-edge vertical farming could be one approach to sustain it.

Among the disruptive innovations which could strengthen food security are high-tech vertical farming, alternative proteins such as plant-based protein, lab-grown protein and vertical aquaculture designs.

Singapore-based company Sustenir Agriculture has come up with a vertical farming system that enables even non-native crops like strawberries or kale to be grown in the space-constrained city-state, while the use of artificial intelligence (AI) further increases productivity.

To push back against overfishing and mangrove destruction, Apollo Aquaculture, a Singaporean seafood farming company, has developed Singapore’s first land-based, vertical farming system for both fish and shrimp.

The use of a recirculating aquaculture system (RAS) means the farm has better control over environmental risks such as algae blooms and disease outbreaks, and does not rely on antibiotics and hormones. It also enables higher and more consistent yields while using less water and land compared to conventional fish farms.

The company plans to deploy its first vertical farm by 2020 and to eventually contribute about five per cent of Singapore’s total fish consumption by 2023.

In an effort to transform the seafood industry, the Singapore-based clean meat company Shiok Meats has taken a different approach towards shrimp production.

A common issue with shrimp monoculture is the susceptibility to disease, which has resulted in the growing use of antibiotics and harmful chemicals in the industry. Therefore, the company decided to try producing a clean variety of this much-loved seafood in the lab, by isolating stem cells from a shrimp and growing them in a nutrient mix in bioreactors.

Aware of the harmful environmental impacts of meat production, and of the fact that few people would be willing to change their diets for the sake of the environment, the Californian food technology firm Impossible Foods produces plant-based protein that looks, feels and tastes exactly like beef, while containing less cholesterol, fat and calories.

The Impossible Burger, made entirely from plant ingredients, needs less land and water, and emits less greenhouse gases than a conventional ground beef burger. Image: Eco-Business

The Impossible Burger, made entirely from plant ingredients, needs less land and water, and emits less greenhouse gases than a conventional ground beef burger. Image: Eco-Business

The now-famous Impossible Burger gets its “meaty” flavour from a protein naturally found in soy roots. One Impossible Burger emits 89 per cent less greenhouse gases and uses only a fraction of the land and water needed as compared to a burger made from cows.

The company, which recently launched in Singapore, aims to eliminate animals from the human food chain by 2035 to make the global food system more sustainable, says company founder Pat Brown.

This article is published in collaboration with Eco-Business.